Look a little closer, and you can see the workers as they add to that strength. While some are using heavy machinery to move walls into place or welding beams to form the superstructure, you’ll notice that many are looking at iPads, small laptops, or even their phones. That’s because this project, like so many in modern construction, depends on technology to get the job done right, on time, and under budget.

“At one time everybody on a job site was carrying blueprints around,” said Craig Johnson, director of construction programs for Collin College. “When you see people out walking around the job site now, you don’t see paper blueprints. There is usually just one large set in the trailer.

“Construction is a complicated process because things are changing constantly, and new information is becoming available throughout the course of the project.”

Since those changes can now be relayed electronically, the project can move faster with fewer mistakes and more accurate information.

“Anytime you can cut a day, a week, or a month off of a project, you are saving ridiculous amounts of money,” Johnson said.

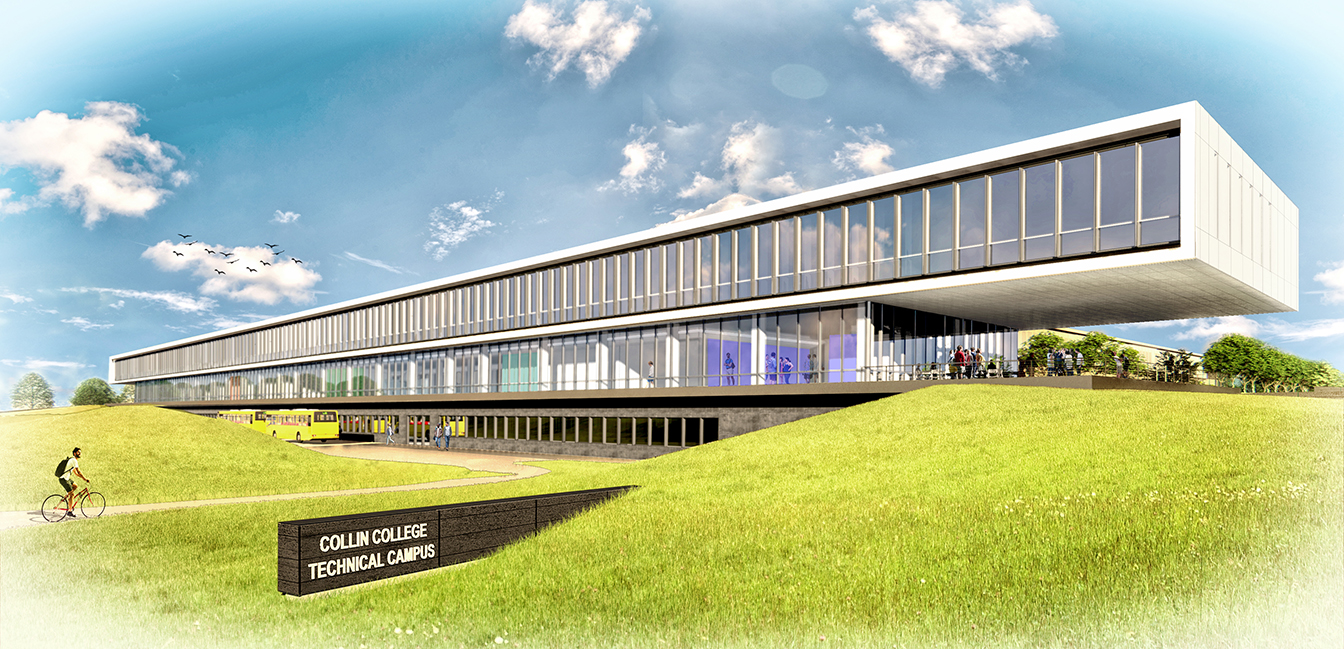

Johnson, who teaches construction management for the college and will oversee the

construction programs at the Technical Campus when it opens in fall 2020, will be

one of the first people to tell you about the benefits of technology in both education

and construction. He won’t be the last, though.

Johnson, who teaches construction management for the college and will oversee the

construction programs at the Technical Campus when it opens in fall 2020, will be

one of the first people to tell you about the benefits of technology in both education

and construction. He won’t be the last, though.

Despite the common but misleading image of the low-wage, low-skilled construction worker or a mechanic with perpetually greasy hands, technology has changed the face of skilled trades and is providing a bright future for workers with the right education.

“One of the things I like to say is that we are training technicians to be as advanced as the vehicles they service,” Shaun Smith, director of automotive and collision repair for the college, said. “Modern cars are not the old, carbureted, leak-oil-out-of-every-orifice type of car they used to be. Some cars don’t even have oil anymore. Some don’t have transmission fluid.”

What newer cars do have are complex computer systems with which a service technician must interface and high-tech components which need someone trained in their operation.

Smith’s curriculum will have students working on electronic vehicle components utilizing the engineer-level multimeters, using the latest automotive scan tools by industry-leading manufacturers, and walking through simulations designed to replicate problems like electrical shorts. The college is also working to secure electric vehicles and cars with autonomous driving technology so that students will have access to the technologies they will be dealing with in a growing number of dealerships, service centers, and collision repair shops in Collin County.

“These jobs are not the $20,000, $40,000 or $50,000 jobs that they were 20 years ago,” he said. “There is potential to make a lot of money and have a really good career with hard work, dedication, and the right education.”

Smith points to a recent trip he took to a collision repair shop in Dallas where top technicians earn $250,000 annually using the kinds of skills he and other faculty will be teaching at the Technical Campus to work on high-end vehicles like Bentleys and Rolls-Royces.

As with any good education, the students at the Technical Campus will build a foundational understanding of the processes involved. They will learn to swing a hammer, weld a pipe, or change the oil on a car – at least on those which require it. The students will balance that basic knowledge and hands-on learning with higher-level studies that will allow them to thrive in growing, opportunity-rich fields.

Brian Sanders, discipline lead for HVAC programs at Collin, smiles broadly as he talks about the opportunities available to HVAC workers with the training his program provides. In addition to teaching the mechanics and maintenance of heating and refrigeration equipment and preparing students for multiple EPA certifications, his program teaches HVAC design and airflow management. Sanders said that testing and balancing using those techniques is a career in itself.

“Testing and balancing is a white shirt job,” Sanders said. “You step out of a clean vehicle. You walk through with the proper equipment. You test, evaluate, and input data into the computer. Then somebody else who doesn’t have your education comes in to make adjustments before you retest. You don’t have to break a sweat. Those job opportunities didn’t exist 10 or 15 years ago. They are huge employment now, and they pay well.”

There is no doubt that the people testing and balancing those systems worked hard learning the basics of air conditioning repair before winning their jobs, but they have built on those basics with more knowledge and skills. Education is the foundation in which a career can be anchored. Much like the Technical Campus, higher education is the structure from which Collin College graduates can extend themselves into the world, making a statement about their purpose and abilities.

Visit www.collin.edu/campuses/technical or email technicalcampus@collin.edu for the latest information about the campus and its programs.